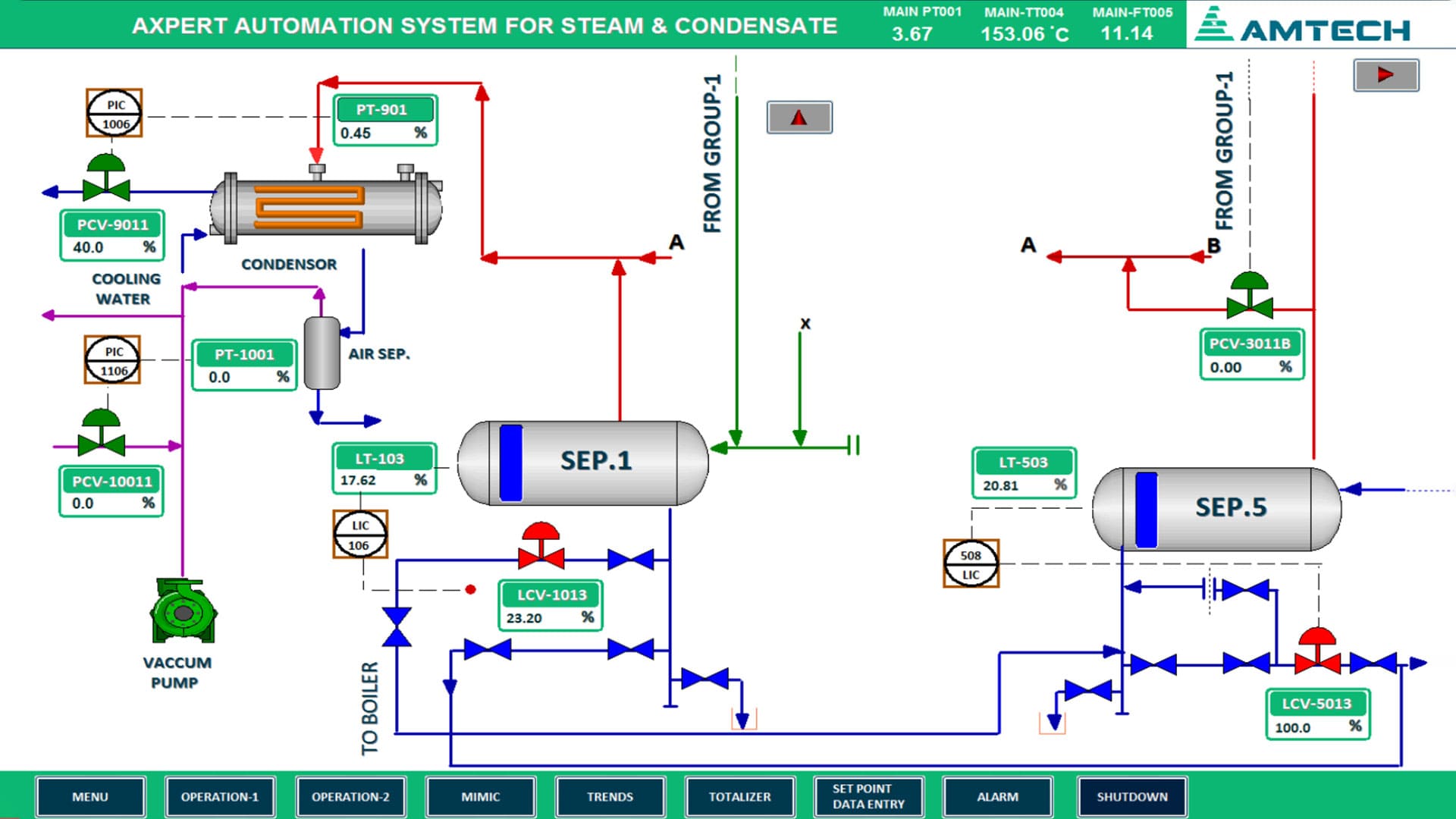

The new generation of control and monitoring system, developed by Amtech, integrates the operation of steam and condensate using SCADA, instrumentation and Automation system for controlling and monitoring.

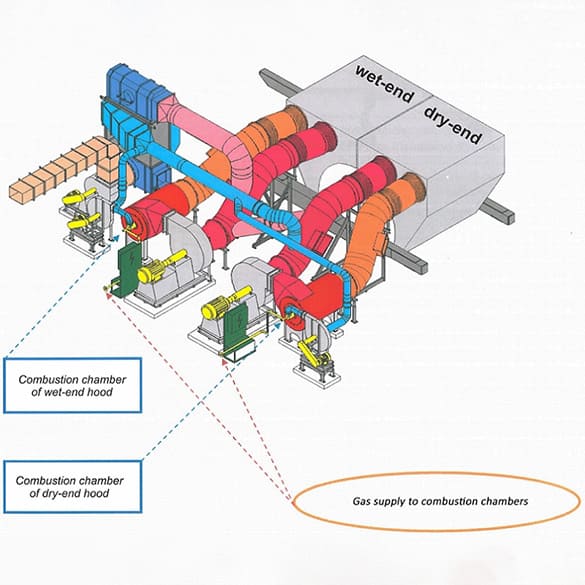

The objective of the steam and condensate system in paper machine is to provide the steam for drying. In the dryer part the moisture is evaporated as the paper is pressed between felt and the hot drying cylinder.

The steam and condensate system is a part of a paper machine. Past the press section, the paper sheet has a water content of about 60%. The final drying is achieved in the drying section. This is achieved by means of several steam heated dryers (cylinders). These are driven in groups of few together. The paper sheet runs over a large number of dryers. The temperature of each of the dryer surfaces must be exactly controlled. In the first group this might be 70 °C (160 °F) and then rises slowly to 105 °C (221 °F) in the later groups at the dry end.